CEO-EDGE full-automatic OCA lamination machine

CEO-EDGE full-automatic OCA lamination machine

- $1,439.40

-

Quantity Price 1- $1,439.40

Product is In Stock

Quantity

Categories: BRAND ACCESSORIES/ FORWARD Machines

CEO-EDGE full-automatic OCA lamination machine

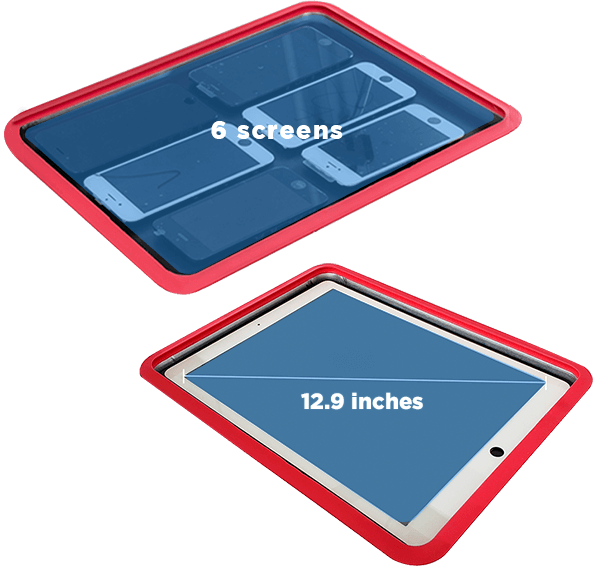

In-frame supported | Largest 15.9 inch | All LCD refurbishing

1.Edge refurbish always fails?

2.The debubble time for edge screen is too long and always has returned bubble?

3. There are always dead bubble for flat screen lamination(specially stick OCA manually)?

4. One machine can never meet all the

requirements?

Edge screen refurbish always fails?

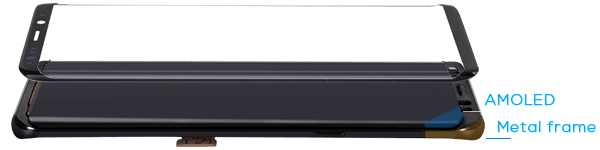

In-frame lamination is one of the most convenient way. It's no need to separate mid-frame, which makes it more easier for operation and reduce the risk of breaking the LCD.

We use special mat to do in-frame lamination with 0 risk and high success rate, it's suitable for beginner to use and operate.

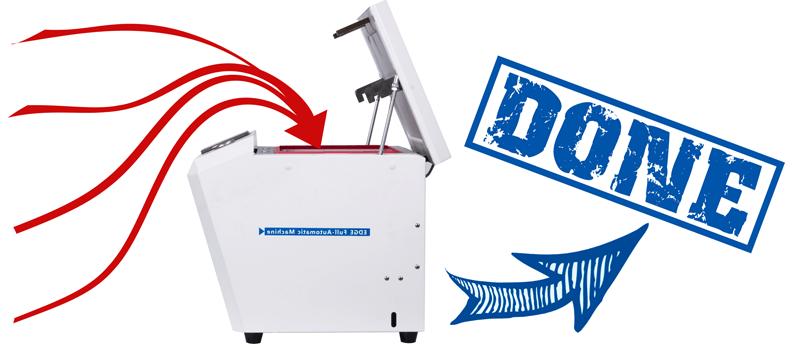

Does it take too much time to debubble edge screen, and always have returned bubbles?

The reason why it's take long time to debubble is that the mat cannot accord with the glass radians completely. Which is leading to severity deformation of OCA glue in the laminating process, so more pressure and longer time are needed for laminating.

Because the debubble process using high pressure and takes a long time, the possibility of returned bubbles increases.

The mold and mat specially designed by FORWARD for the CEO machine can laminate the edge screen almost with bubble-free, and then the bubble removal time only need 2 minutes. The bubble removal pressure only need 4kg/cm². If you do like that, your LCD can achieve 0 returned bubble. It can improve your refurbish efficiency and reduce cost.

Flat lcd fit always shows dead bubbles (bubble that cannot be removed),

causing rework?

From the feedback of many novice customers, we know that when they are fitted with the Flat lcd of the MI series and the Samsung series, they are prone to dead bubbles and cannot be removed, resulting in the need to re-separate and fit again. Seriously reduced work efficiency.

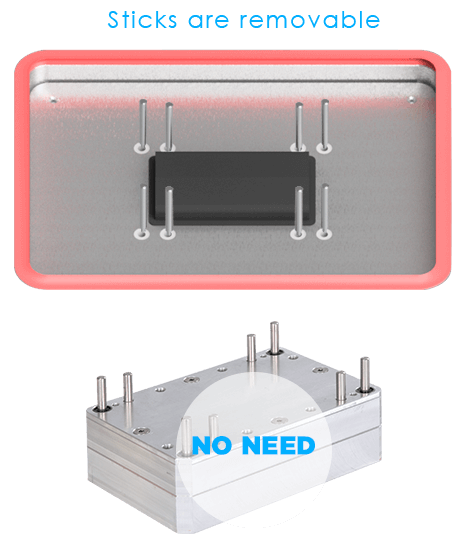

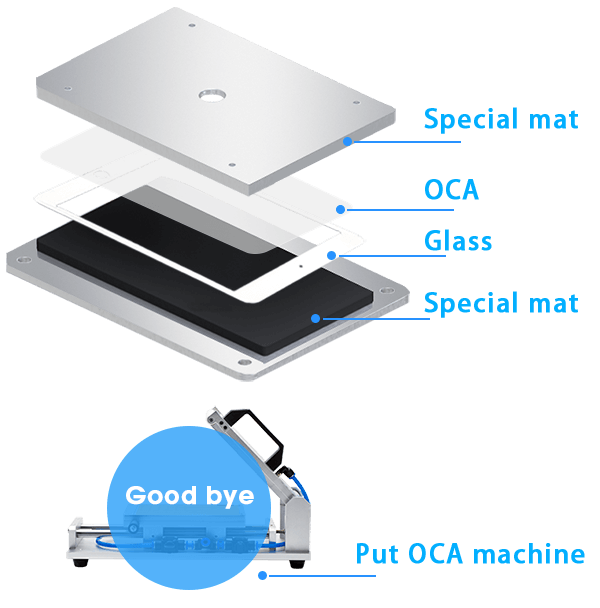

From the analysis of more than 100 cases, we came to a conclusion. If there is a dead bubble in the fit, the problem must come from the bad operation of manually attaching OCA. Because the push wheel operation is used, it is difficult for the novice to control the force, and it is easy to deform the OCA, thereby generating a dead bubble.

Therefore, we have developed this mold, firstly we need to do vacuum extraction and then slowly press down vertically to ensure that the OCA fit does not deform, no bubbles. Therefore, the LCD&OLED does not require rework, which greatly improves the work efficiency.

Flat LCD solution:

Have you found that there is no single machine on the market that can meet all your needs?

Yes, now there is not exist a machine to solve all broken screens on the market. Some machines can solve the problem of edge screen, but it can't solve the problem of large-size LCD and ipad. Some machines can refurbish large-size screens, but they can't solve the problem of edge screen.

The CEO machine can refurbish edge screen and 0-12.9 inch flat screen, one machine can meet the needs of all models of the screen. No need to buy extra machine.

Product parameters:

| Brand | FORWARD | Model | CEO |

| Name | CEO-EDGE full-automatic OCA lamination machine | Voltage | 220/110V |

| Power | 1200W | Pressure | 0~6.7kg/cm² |

| Before weight | 51KG | After weight | 58KG |

| Before packing | 460X460X407MM | After packing | 530X530X495MM |

CEO-EDGE full-automatic OCA lamination machine